Indoor Fiber Optic Cables

For termination and maintenance, branching fiber optic cable facilitates the independent cabling or branching of each fiber. Branch fiber optic cables are available in three different configurations: 2.8mm subunits for heavy service applications; 2.4mm subunits for normal service applications; and 2.0mm subunits for low service applications. These branch cable applications can be placed in ducts under the freeze point line between buildings, in upward-facing risers within buildings, under the floor of computer rooms and fiber to the desktop.

20 results

ViewShowcase

ADSS cable is loose tube stranded. Fibers, 250μm , are positioned into a loose tube made of high modulus plastics.

GJFJU-1F Outdoor single core tight-buffered aerial fiber optic cable is a single core optical fiber.

GJFJU-1F Outdoor single core tight-buffered aerial fiber optic cable is a single core optical fiber.

which is suitable for the construction of indoor distributed base stations.

GJPFJV Break-out cable is made by the tight buffer fiber wrapped with a layer of aramid yarn as strength member units.

Operating Temperature -40°C to + 70°C

Installation Aerial/Direct Buried/Duct

Installation Aerial/Direct Buried/Duct

The sub unit and FRP are twisted into a circle, and PVC sheaths are extruded into cables.

The optical fiber in the sub cable adopts the tight sleeve design, and has independent reinforcement elements and sheaths

The outermost layer is made of 8-shaped PVC or LSZH sheath.

GJFJU-1F Outdoor single core tight-buffered aerial fiber optic cable is a single core optical fiber.

GJFJHV cable is made by the tight buffer fiber wrapped with a layer of aramid yarn as strength member units.

GJBFJV cable is made by the tight buffer fiber wrapped with a layer of aramid yarn as strength member units.

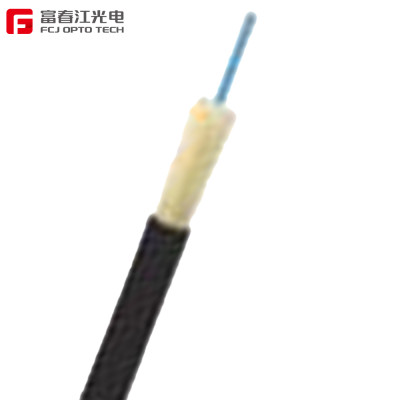

Tight Buffered Fiber is produced as that fiber is sheathed by buffer material.The selection of top-quality fiber.

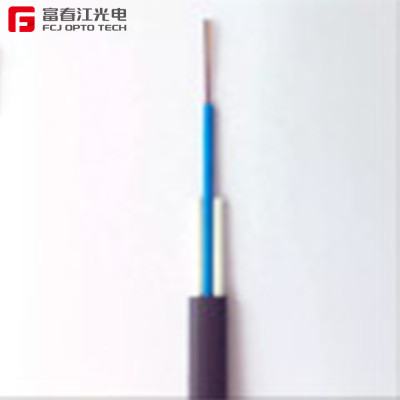

Loose Buffered Fiber cable is produced as that fiber is sheathed by buffer material.The selection of top-quality fiber

GJFV 2-24 OM3 Colored cable is made by evenly applying strands of Aramid yarns as the strength member over ф250μm fibers.

GJFJV SM Tight cable is made by evenly applying strands of Aramid yarns as the strength member.

GJPFJV Break-out cable is made by the tight buffer fiber wrapped with a layer of aramid yarn as strength member units.

GJFJV 2-24 Tight indoor fiber optic cable is made by evenly applying strands of Aramid yarns or High strength glass yarns.

GJFJH Break-out cable,the tight buffer fiber is placed on the surface with a layer of aramid yarn as strength member units.

The 300μm Tight buffered fiber optical cable is made of Hytrel-7246 grade material