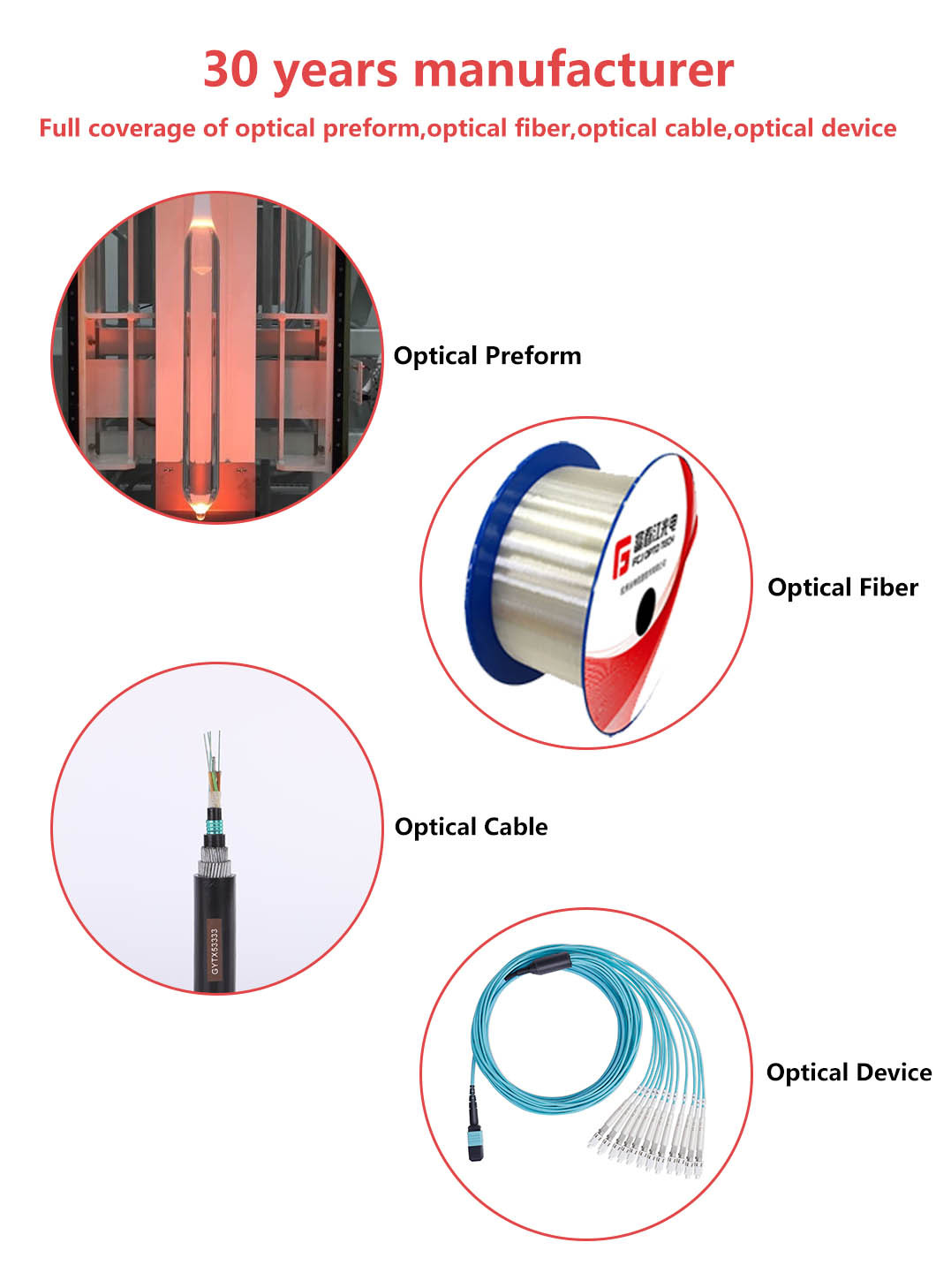

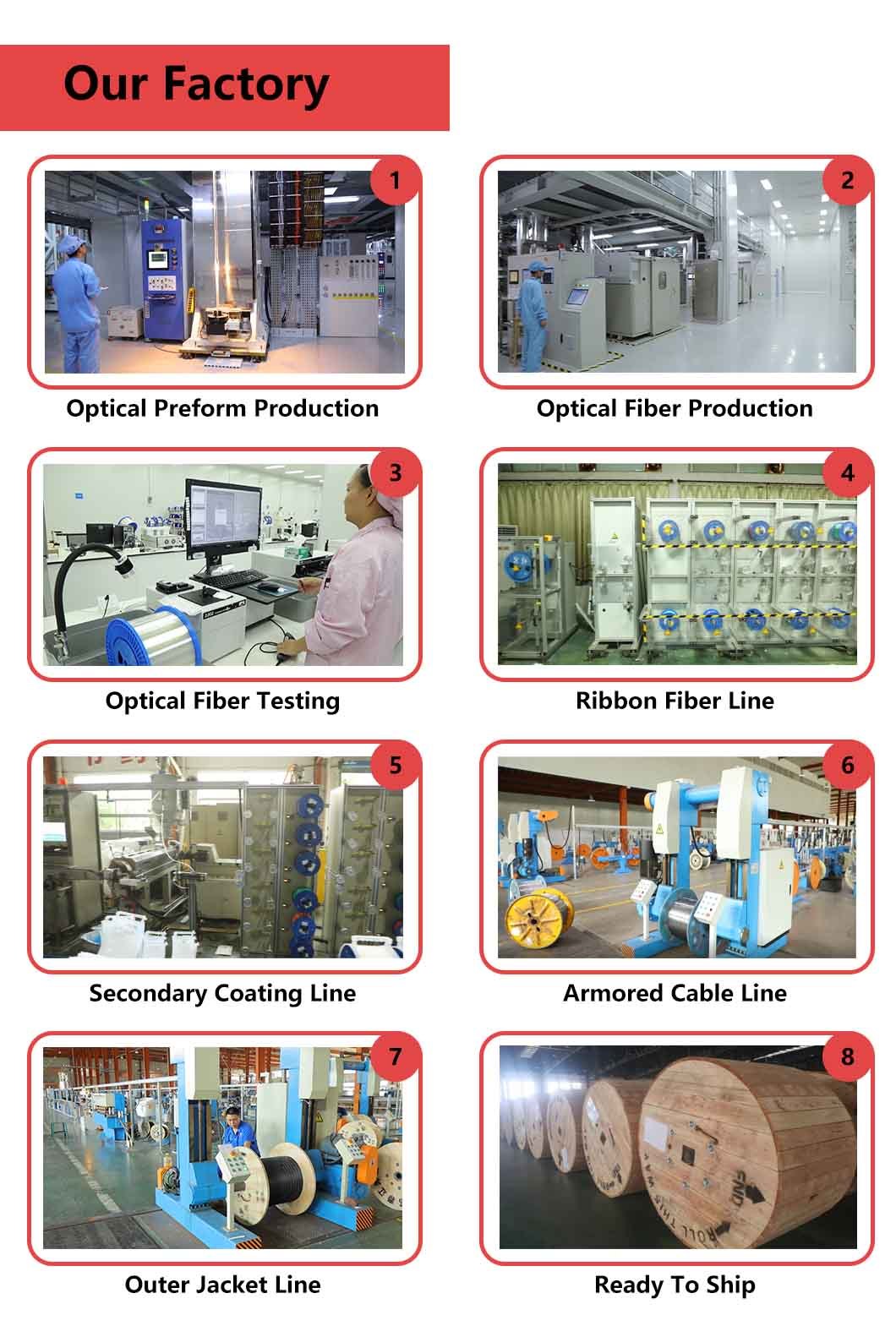

FCJ factory 80M span 6-core ADSS Single jacket All Dielectric Self-supporting Aerial fiber optic cables

FCJ factory 80M span 6-core ADSS Single jacket All Dielectric Self-supporting Aerial fiber optic cables

ADSS cable Structural features:Single layer ,Loose tube stranding, Non-metal strength member, Half dry water-blocking, Aramid yarn strength member, PE outer jacket. it adopts the twisted structure of loose sleeve layer, 250 μm optical fiber is inserted into the loose tube made of high modulus materials, and the loose tube is filled with waterproof compounds. The loose tube ( and filling rope ) is twisted around the non-metallic center reinforcing core ( FRP ) to synthesize a compact cable core. The gap of the cable core is filled with a water-blocking yarn and a water-blocking belt longitudinally wrapped by the cable core, and then the aramid fiber that plays a reinforcing role is twisted. Finally, the polyethylene ( PE ) outer sheath or the electric mark ( AT ) outer sheath is extruded.

1、Optical

fiber performance

|

Item |

Contents |

Value |

|

Type |

SM

G.652D |

|

|

Cladding Diameter |

125.0±0.7um |

|

|

Coating Diameter |

243.0±0.7um |

|

|

Mode-Field

Diameter (MFD) |

1310nm |

9.2±0.4um |

|

1550nm |

10.4±0.6um |

|

|

Attenuation |

1310nm |

≤0.34 dB / km |

|

1383nm |

≤0.34 dB / km |

|

|

1550nm |

≤0.20dB / km |

|

|

Zero Dispersion Wavelength(λ0) |

1312±12

nm |

|

|

Zero Dispersion Slope(S0) |

≤0.092

ps/(nm2.km) |

|

|

Cable Cutoff Wavelength λcc |

≤1260nm |

|

|

Macrobend Loss |

100 turns, Φ50mm@1310nm&1550nm |

≤0.05

dB / km |

|

Proof Test |

≥9.0N,

≥1.0%, ≥100Kpsi |

|

2、Cable

identification

Fibre & Loose tube colour code

|

NO. |

1 |

2 |

3 |

4 |

5 |

6 |

|

Colour |

|

|

|

|

|

|

|

NO. |

7 |

8 |

9 |

10 |

11 |

12 |

|

Colour |

|

|

|

|

|

|

3、Cable

assembly & dimensions

|

Item |

Contents |

Unit |

Value |

|||||||

|

Fiber |

Number |

/ |

6 |

12 |

24 |

36 |

48 |

72 |

96 |

144 |

|

Loose

tube |

Material |

/ |

PBT |

|||||||

|

Number |

/ |

1 |

2 |

4 |

6 |

4 |

6 |

8 |

12 |

|

|

Ouder

diameter |

mm |

1.9 |

2.0 |

2.2 |

2.0 |

2.2 |

2.2 |

|||

|

Max

fiber per tube |

/ |

6 |

6 |

12 |

12 |

12 |

12 |

|||

|

Water

blocking material |

/ |

Jelly

compound |

||||||||

|

Central

strength member |

Material |

/ |

FRP |

|||||||

|

Ouder

diameter |

mm |

1.5 |

2.0 |

1.8 |

2.1 |

2.8 |

3.5 |

|||

|

PE

layer diameter |

mm |

/ |

/ |

/ |

/ |

3.7 |

6.4 |

|||

|

Water

blocking |

Material |

/ |

Water

blocking yarns/tape |

|||||||

|

Sterngth member |

Material |

/ |

Aramid

yarns |

|||||||

|

Number |

/ |

Determined according to the

use requirements |

||||||||

|

Outer

sheath |

Material |

/ |

HDPE |

|||||||

|

Colour |

/ |

Black |

||||||||

|

Thickness |

mm |

1.6 |

||||||||

|

Marking |

Material |

/ |

Printing

Ink |

|||||||

|

Color |

/ |

White |

||||||||

|

Way |

/ |

Ink-jet printing |

||||||||

|

Content |

/ |

(Producers+Type+Date of

production+Meter)Or Specify the

content |

||||||||

|

Drum |

Material |

/ |

Export bakelite plate drum |

|||||||

|

Optical

cable |

Ouder

diameter |

mm |

8.9 |

9.6 |

9.7 |

9.7 |

11.6 |

14.4 |

||

|

Weight |

Kg/Km |

59 |

65 |

67 |

63 |

98 |

151 |

|||

|

MAT |

KN |

1.3 |

1.5 |

1.5 |

1.6 |

2.1 |

3.0 |

|||

|

RTS |

KN |

1.8 |

2.3 |

2.1 |

2.3 |

3.3 |

4.7 |

|||

4、Mechanical

& Environmental Performance

|

Item |

Contents |

Value |

|

MAX.

Crush resistance |

Short |

1000N/100mm |

|

MIN.

Bending radius |

Operation |

12.5D |

|

Installation |

25D |

|

|

Temperature

range |

Installation |

-10℃~60℃ |

|

Operation |

-30℃~70℃ |

|

|

Storage/transportation |

-30~70℃ |

5、Main

mechanical & environmental performance test

|

Item |

Test

Method |

Acceptance

Condition |

|

Tensile

Strength IEC

60794-1-2-E1 |

Load:MAT |

Finer

strain ≤0.33% |

|

Length

of cable:≥50m |

Loss

change after test(1550nm)≤0.1dB |

|

|

Load

time:1min |

No

fiber break and no sheath damage |

|

|

Crush

test IEC

60794-1-2-E3 |

Load:Short term crush |

Loss

change after test(1550nm)≤0.1dB |

|

Load

time:1min |

No

fiber break and no sheath damage |

|

|

Impact

test IEC

60794-1-2-E4 |

Weight:0.45KG |

Loss

change (1550nm)≤0.1dB |

|

Height:1meter |

||

|

Radius:12.5mm |

No

fiber break and no sheath damage |

|

|

Times:≥5 |

||

|

Repeated

Bending IEC

60794-1-2-E6 |

Bending

radius:≤20D |

Loss

change (1550nm)≤0.1dB |

|

Wdight:150N |

No

fiber break and no sheath damage |

|

|

Times:30 |

||

|

Water

penetration IEC

60794-1-2-F5 |

Height

of water:1m |

No

water leak from the cable core of the opposite end |

|

Sample

length:3m |

||

|

Time:24h |

||

|

Temperature

cycling IEC

60794-1-2-F1 |

Temperature:-40℃~70℃ |

Loss

change (1550nm)≤0.1dB |

|

Time

of each step:12h |

No

fiber break and no sheath damage |

|

|

Number

of cycle:2 |

6、Packing

---Each single cable length been wound on an

Export

bakelite

plate drum or pure wooden drum;

---Standard drum length is 4000m or Specify

the length;

---At least 3m of cable inner end should be

reserved for testing;

---Covered by plastic buffer sheet;

---Sealed by strong wooden drum

- Loading...

- *Title

- *Content